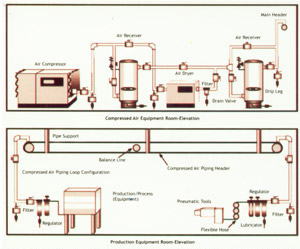

The purpose of the compressed air pipng system is to deliver compressed air to the points os usage. The compressed air needs to be delivered with enough volume, appropriate quality and pressure to properly power the components that use the compressed air. Compressed air is costly to manufacture. A poorly designed compressed air system can increase energy costs, promote euipment failure, reduce production efficiencies, and increase maintenance requipments. It is generally considered true that any additional costs spent improving the compressed air pipng system will pay for themselves many times over the life of the system.

Compressor Discharge Piping

Discharge Piping from a compressor without an integral after cooler can have very high temperatures. The pipe that is installed here must be able to hadle these temperatures. The high temperatures can also cause thermal expansion of the pipe, which can stress to the pipe. Check the compressor manufacturer's recommendations on discharge piping. Install a liquid filled pressure gauge, a thermometer and a thermowell in the dischage airline before the after cooler. Proper support and flexible discharge pipe can eliminate strain.

|

|